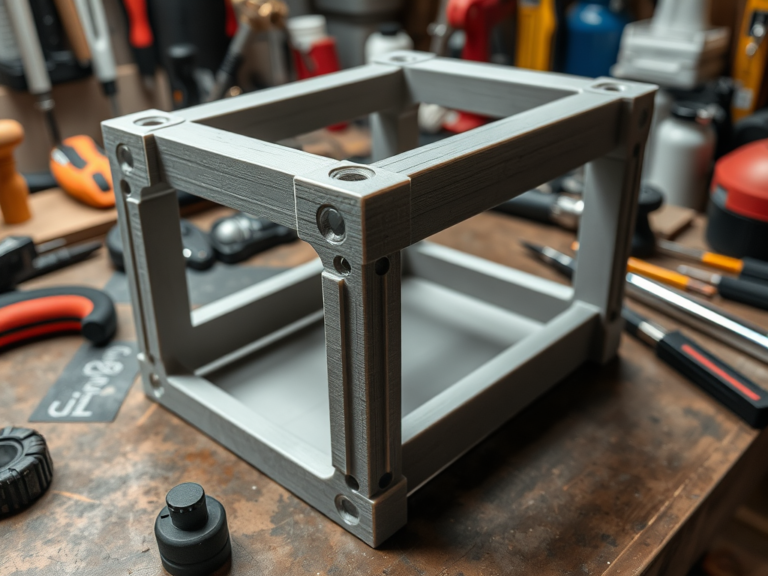

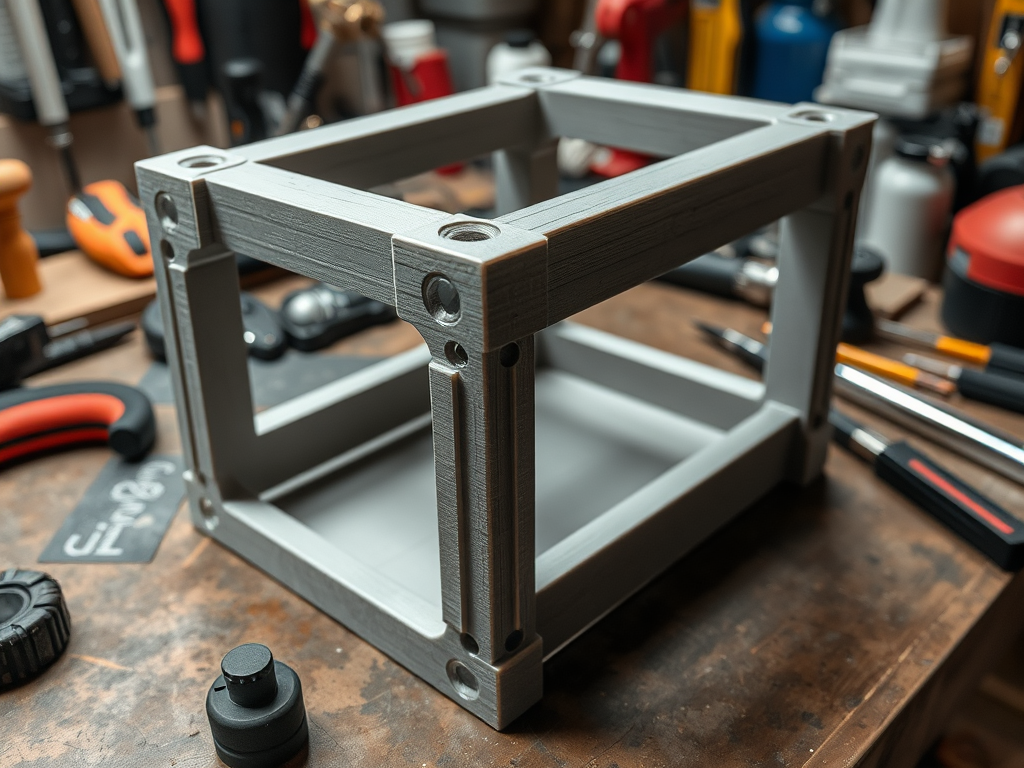

A strongback is an essential support structure used in various applications, from model building to larger engineering projects. 3D printing offers a versatile way to create strongbacks that are tailored to your specific needs. This guide will walk you through the process of designing and printing your strongback, ensuring it meets all functional requirements. From boat building to construction to aerospace manufacturing, the 3D printed strongback is transforming structural reinforcement and precision alignment across several sectors. Made historically from metal or wood, strongbacks provide a solid frame to ensure correct alignment and structural integrity during construction.

Advantages of a 3d-Printed Strongback

1. Accuracy and Customising

Customised strongback designs made possible by 3D printing meet exact project requirements, therefore guaranteeing improved alignment and support.

2. Strong & Lightweight

3D printed strongbacks can be lightweight but robust, using cutting-edge materials like reinforced PETG or carbon-fibre-infused filaments.

3. Economic Manufacturing

Producing traditional strongbacks made of metal or wood can be costly and time-consuming. 3D printing speeds up manufacturing, cuts labour expenses, and removes waste.

4. Simple, Modular Assembly Technique

Interlocking components allow printed strongbacks to be built, therefore facilitating transportation and installation.

5. Fast Design Testing and Prototyping

Using 3D printing allows designers and engineers to iterate and test several strongback designs faster and easier.

A 3d-Printed Strongback Is:

In manufacturing, a strongback is a structural support system meant to keep alignment and strengthen structural integrity. Strongbacks are perfect for uses requiring accuracy since 3D printed versions may be tailored to particular forms, sizes, and weight tolerances.

Typical Applications for 3d-Printed Strongbacks

- Boat Building: Guarantees alignment and hull symmetry.

- Construction and Architecture: Used in modular assembly, scaffolding, and concrete shaping.

- Aerospace and Automotive: Provides lightweight support systems for manufacturing aircraft and cars.

- Robotics and Engineering: Regular fixtures for industrial component assembly.

Superior Materials for 3d Printing Strongbacks

1. PETG (Polyethene Terephthalate Glycol)

✔ High strength and flexibility

✔ Heat and impact resistance

✔ Ideal for: Automobile and building applications

2. Carbon Fibre Reinforced PLA/PETG

✔ Lightweight yet remarkably strong

✔ Great stiffness and rigidity

✔ Ideal for: Robotics, aerospace, and boat building

3. ABS (Acrylonitrile Butadiene Styrene)

✔ Durable and impact-resistant

✔ Can be post-processed with acetone for a smooth finish

✔ Requires a heated bed for optimal printing

✔ Ideal for: Industrial engineering applications

4. Nylon

✔ Resistant to chemicals and moisture

✔ Superior toughness and elasticity

✔ Ideal for: Structural reinforcement of a heavy-duty nature

Perfect 3d Print Settings for Strongbacks

1. Layer Height and Resolutions

- 0.2mm to 0.3mm for a balance between print speed and strength.

- 0.1mm for more finely detailed strongbacks.

2. Infill Density

- 50%–80% infill for high-strength applications.

- 30% infill for sturdy yet lightweight strongbacks.

3. Print Direction and Supports

- Lay the strongback flat on the print bed for best layer adhesion.

- Enable support for overhangs greater than 45°.

4. Printing Speed and Cooling

- 40 to 60 mm/s for steady, robust layers.

- Turn off component cooling for ABS, but leave PLA and PETG enabled.

5. Bed Adhesion

- Use a heated bed (50–80°c for PETG, 90°c for ABS, and 100°c for Nylon).

- Apply PEI sheets or glue sticks to prevent warping.

Typical Problems and 3d-Printed Strongbacks’ Troubleshooting Guide

1. Warping and Layer Separation

Solution: Use a heated bed and an enclosure to maintain consistent temperatures.

2. Weak Structural Integrity

Solution: Increase infill density and wall thickness to raise strength.

3. Bad Layer Adhesion

Solution: Print at slower rates and slightly raise the hot-end temperature.

4. Overhangs & Print Defects

Solution: Enable support for intricate designs and lower print speed for accuracy.

5. Nozzle Clogging with Fibre-Reinforced Filaments

Solution: Use a hardened steel nozzle (0.6 mm or larger) to handle abrasive filaments.

READ MORE – 3D Printed Small Motor Holders: Crafting Custom Solutions for Your Projects

FAQs:

1. Are heavy-duty uses for a 3d printed strongback possible?

Yes! Strongbacks printed in carbon fibre, PETG or Nylon can withstand significant stresses and loads.

2. How long does 3D printing a strongback take?

Print times depend on size and intricacy, ranging from 4 to 24 hours.

3. How should a multi-part strongback be assembled best?

Create overlapping joints and secure them with bolts, adhesives, or friction-fit mechanisms.

4. Could a 3d-printed strongback replace a metal strongback?

Yes, for some applications. While metal is still superior for extreme loads, 3D printed strongbacks offer lightweight customisation.

5. Where can I obtain 3D printable strongback designs?

You can find free STL files on:

- Thingiverse

- Printables

- GrabCAD

- Cults3D

Conclusion

Custom, sturdy, and reasonably priced strongbacks made possible by 3D printing now find application in many different sectors. Whether you’re working in boat building, construction, robotics, or aerospace, a 3d printed strongback provides precision, strength, and versatility.By choosing the correct materials, print settings, and reinforcement procedures, strongbacks that match traditional materials can be produced, saving money and improving efficiency.